We are experts in working with a wide range of engineered plastic materials, ensuring that we select the best material for your specific application. Our material options include:

ABS, PP, PE, PS, PVC, PET

Nylon, Polycarbonate, POM, Acetal, PEEK

TPU, TPE, High-Temperature Polymers, Biodegradable Plastics

Glass-filled, carbon fiber-reinforced plastics

We carefully choose the right material based on your requirements for durability, impact resistance, chemical resistance, and flexibility.

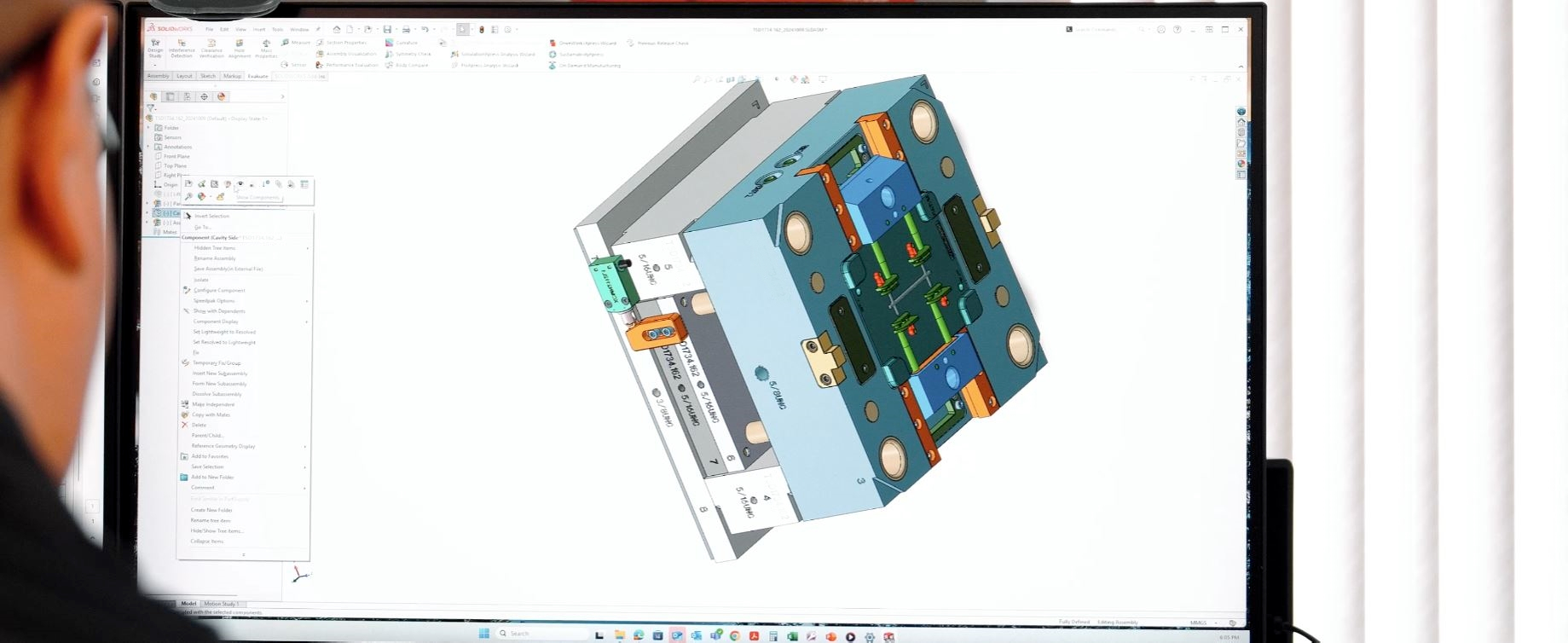

Our engineering team works closely with clients to develop custom solutions, from initial product design to final production. We use advanced 3D CAD software, prototyping, and simulation tools to create designs that meet exact specifications.

Rapid prototyping using 3D printing and CNC machining to test form, fit, and function before full production.

We have in-house capabilities to design and build custom molds, dies, and tooling to ensure the highest precision and cost efficiency.

We use advanced engineering to create components and molds to optimize the manufacturing process.